In industrial and manufacturing environments, efficiency and precision are essential for maintaining high-quality production standards. Among the many tools that support surface finishing and material handling processes, coating hooks and coating hooks and racks play a critical yet often underestimated role. These components are designed to suspend parts securely during coating, painting, powder coating, plating, and drying processes, ensuring consistent coverage and smooth workflow. When chosen and used correctly, coating hooks and racks improve productivity, reduce waste, and contribute significantly to the final appearance and durability of finished products.

Introduction to Coating Hooks and Racks

Coating hooks and racks are specialized fixtures used in industrial finishing operations to hold, organize, and transport components during surface treatment. Their main purpose is to support parts in a way that allows full exposure to coatings while minimizing contact points that could cause imperfections. Whether used in automated conveyor systems or manual coating setups, these tools ensure stability, balance, and uniform spacing, which are all crucial for achieving high-quality results. As production demands increase, well-designed hooks and racks become essential for maintaining speed without sacrificing precision.

What Are Coating Hooks and Why They Matter

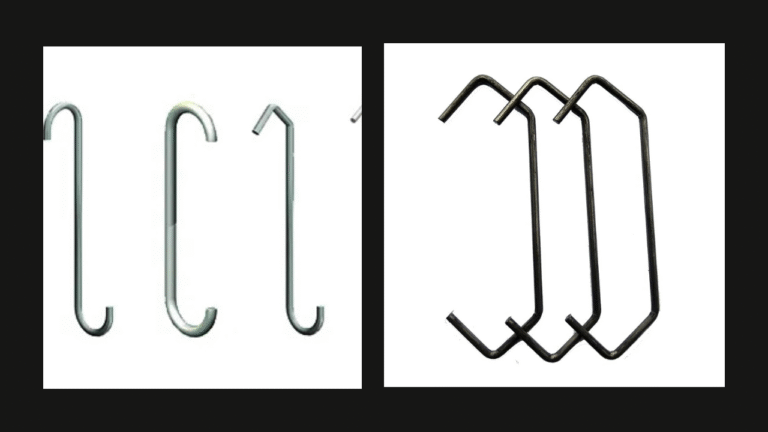

Coating hooks are metal fixtures engineered to suspend individual parts during finishing processes. They are commonly used in powder coating, liquid painting, electrostatic spraying, and plating operations. The design of a coating hook must provide a secure grip while allowing easy loading and unloading of parts. Hooks are manufactured in various shapes such as S-hooks, V-hooks, C-hooks, and custom forms, each suited to different part geometries and weight requirements.

The effectiveness of a coating hook directly influences coating quality. A properly designed hook ensures even exposure to the coating material, reduces shadowing, and minimizes defects caused by movement or poor positioning. In electrostatic applications, hooks also play a role in maintaining proper grounding, which helps coatings adhere evenly to the surface of the part.

Understanding Coating Racks and Their Function

While coating hooks support individual items, coating racks serve as the structural framework that holds multiple hooks and parts together. Racks allow several components to be processed simultaneously, improving efficiency and consistency across production runs. They are designed to maintain uniform spacing between parts, which prevents contact during coating and curing stages.

Coating racks come in various designs, including fixed racks for repetitive production and modular racks for flexible operations. Adjustable racks are particularly useful in facilities that handle parts of varying sizes, as they allow quick reconfiguration without disrupting workflow. A well-designed rack system enhances productivity by reducing handling time and improving part organization throughout the finishing process.

Materials Used in Coating Hooks and Racks

The materials used to manufacture coating hooks and racks are chosen for strength, durability, and resistance to harsh environments. Common materials include carbon steel, stainless steel, and spring steel. Carbon steel offers high strength and cost efficiency, making it suitable for heavy-duty applications. Stainless steel is often selected for environments exposed to moisture or chemicals due to its corrosion resistance.

Spring steel hooks are valued for their flexibility and ability to return to shape after repeated use. These properties are particularly important in high-temperature applications such as powder coating ovens, where hooks must endure repeated heating and cooling cycles without losing integrity. Selecting the right material ensures long service life and consistent performance.

Types of Coating Hooks for Different Applications

There are many types of coating hooks, each designed to meet specific industrial needs. S-hooks are among the most common due to their simplicity and versatility. V-hooks provide improved contact and stability for certain part shapes. C-hooks are useful for hanging multiple parts in sequence, increasing efficiency for batch processing.

Custom-shaped hooks are often developed for unique components or specialized production lines. These hooks are tailored to match the exact geometry of the part, ensuring secure suspension and optimal coating coverage. Choosing the right hook type helps reduce rework, prevent damage, and maintain consistent quality.

Different Designs of Coating Racks

Coating racks vary in size, shape, and complexity depending on the application. Simple horizontal racks are suitable for small-scale operations, while multi-tiered racks are used in high-volume production environments. Modular rack systems allow operators to add or remove hooks easily, making them ideal for facilities with frequently changing production requirements.

Some racks are designed to integrate seamlessly with conveyor systems, enabling automated movement through washing, coating, curing, and cooling stages. These designs improve efficiency and reduce manual handling, which lowers the risk of errors and workplace injuries.

Benefits of Using High-Quality Coating Hooks and Racks

Investing in durable coating hooks and racks offers numerous benefits. First, they improve coating consistency by maintaining proper spacing and orientation of parts. Second, they enhance productivity by allowing multiple items to be processed simultaneously. Third, they reduce material waste by minimizing defects caused by poor hanging or movement during coating.

High-quality hooks and racks also contribute to workplace safety by securely holding parts and reducing the risk of drops or collisions. Over time, these benefits translate into lower operating costs, higher output, and improved customer satisfaction.

Industrial Applications of Coating Hooks and Racks

Coating hooks and racks are widely used across many industries, including automotive manufacturing, metal fabrication, electronics, and general manufacturing. In automotive plants, they support components such as brackets, frames, and panels during corrosion-resistant coating processes. In metal fabrication shops, they help organize and process large volumes of small parts efficiently.

Electronics manufacturers rely on precise hook and rack systems to ensure delicate components receive uniform finishes without damage. Powder coating facilities, in particular, depend on these tools to maintain grounding and achieve consistent, high-quality finishes on every part.

Choosing the Right Coating Hooks and Racks

Selecting the right coating hooks and racks requires careful consideration of several factors. Load capacity is critical, as hooks must support the weight of parts without bending or deforming. Part geometry and size determine the appropriate hook shape and rack spacing. Environmental conditions, such as temperature and chemical exposure, influence material selection.

Facilities should also consider production volume and flexibility needs. Modular systems are ideal for operations with frequent changeovers, while fixed systems work well for standardized, high-volume production. Making informed choices ensures long-term efficiency and reliability.

Maintenance and Care for Long-Term Performance

Proper maintenance extends the lifespan of coating hooks and racks and ensures consistent performance. Regular inspection helps identify wear, deformation, or excessive coating buildup. Cleaning hooks periodically prevents grounding issues and ensures secure contact with parts.

Racks should be checked for alignment and structural integrity, especially in high-use environments. Replacing worn hooks promptly and training staff on proper loading techniques further reduces downtime and maintains finish quality.

Conclusion

Coating hooks and racks are essential components in industrial finishing operations, providing the foundation for efficient, organized, and high-quality coating processes. Though simple in appearance, their impact on productivity, finish quality, and operational safety is significant. By choosing durable materials, appropriate designs, and maintaining them properly, businesses can optimize their coating processes and achieve consistent, professional results. Investing in reliable coating hooks and racks is not just about organization—it is a strategic decision that supports long-term operational success.